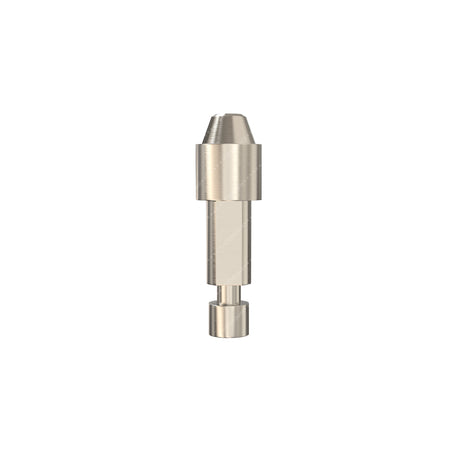

DSI® Conical Compatible

Implant CAD/CAM 3D Analog Regular Platform (RP)

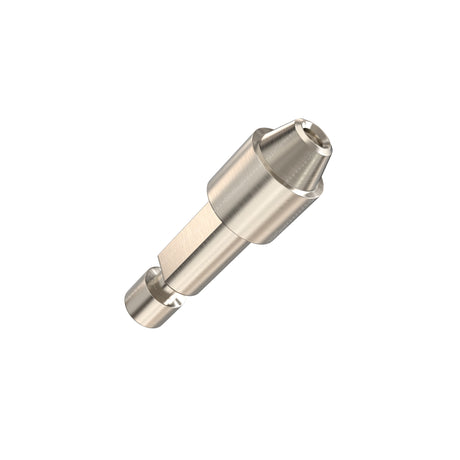

$15.00Unit price /UnavailableDSI® Conical Compatible

Implant CAD/CAM 3D Analog Narrow Platform (NP)

$15.00Unit price /Unavailable OEM Services

OEM ServicesCan't Find Your Connection?

(929) 442-0773

M-F 9am-5pm EST