Mastering Dental Implants: The Guide for Dentists, Lab Technicians, and Clinicians

At OEMDent, we believe that learning about dental implants should be like embarking on a fun and enlightening adventure. Whether you’re a dental professional or simply curious about how implants work, this guide will walk you through everything - from the basics of implant design to the finer points of connection types, sizes, and angles.

Why Dental Implants Matter

Dental implants do more than just replace missing teeth. They restore natural function, help preserve your jawbone, and keep your smile looking its best. In short, they:

-

Improve Chewing and Speaking: Mimicking natural teeth, implants make everyday tasks easier.

-

Enhance Aesthetics: Implants look and feel like real teeth, boosting confidence.

-

Preserve Bone Health: They help maintain the jawbone, preventing bone loss over time.

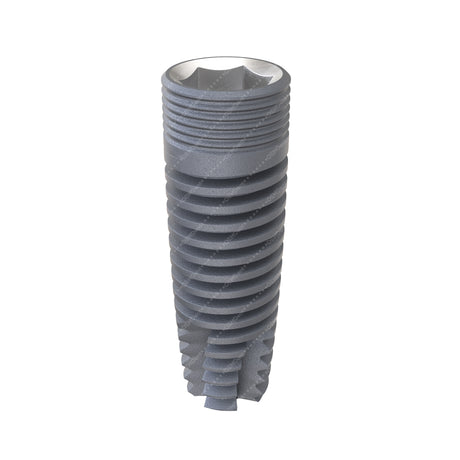

The Heart of an Implant: Understanding the Fixture

At the center of every dental implant is the fixture - a small, precision-engineered component that acts like an artificial tooth root. This fixture is designed to integrate securely with your jawbone, providing a strong base for the visible part of the tooth.

Components of an Implant Fixture

-

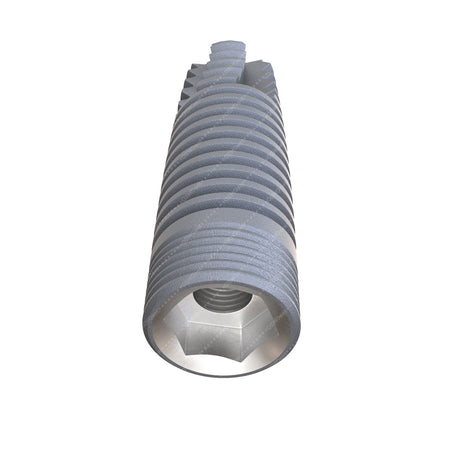

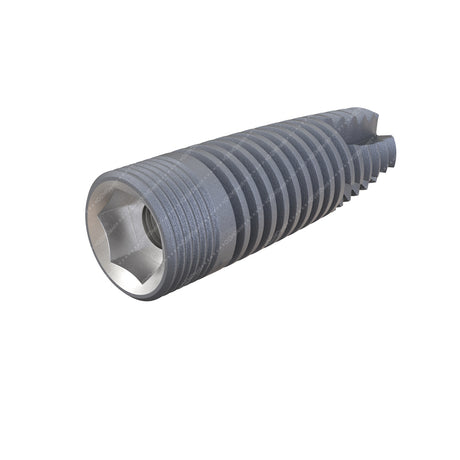

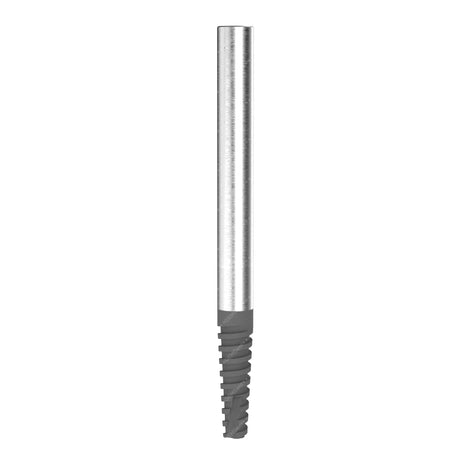

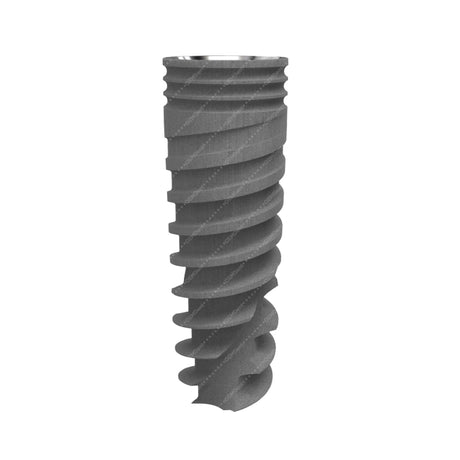

The Implant Body:

This part is embedded in the bone. Its length, diameter, and shape are carefully designed to ensure optimal support and stability.

-

Shapes for Different Situations:

-

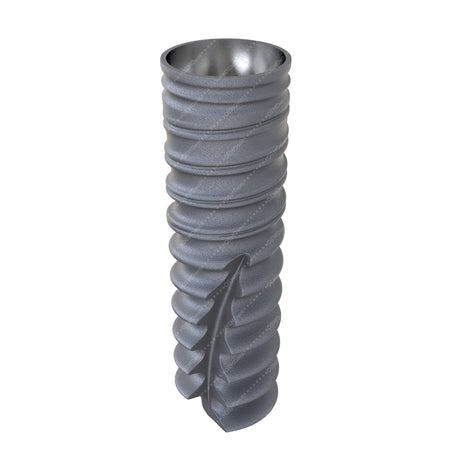

Tapered Fixtures: These narrow at the tip, closely mimicking a natural tooth root. They are ideal for areas where bone volume is limited.

-

Parallel Walled Fixtures: These maintain a consistent diameter, distributing forces evenly in dense bone regions.

-

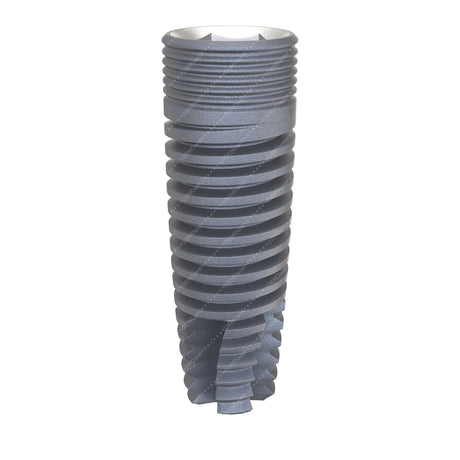

Thread Design:

Threads are like the grooves on a screw, helping the implant grip the bone:

-

V-Shaped Threads: Provide a secure initial hold by gently cutting into the bone.

-

Buttress Threads: Distribute biting forces evenly, making them great for handling heavier loads.

-

Square Threads: Offer balanced force distribution, especially useful in softer bone.

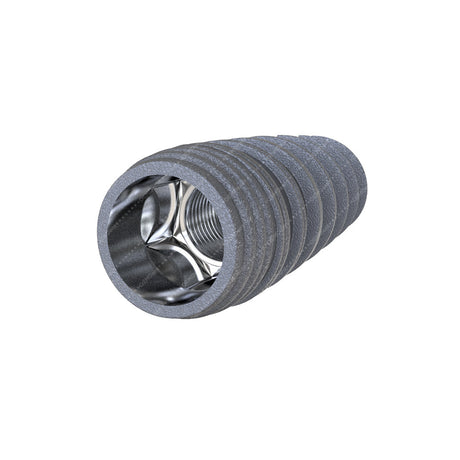

Enhancing Integration with Surface Modifications

The success of an implant depends on how well it bonds with the bone. To encourage this, the implant’s surface is specially treated:

-

Sandblasting and Acid Etching: Create a rough texture so bone cells can latch on like water in a sponge.

-

Plasma Spraying: Adds a thin, bioactive layer that speeds up bone growth.

-

Hydrophilic Coatings: Improve the implant’s ability to attract proteins and cells, accelerating healing.

Material Science: What’s Under the Hood

The choice of material is key to an implant’s performance:

-

Titanium: The most common material due to its strength, lightness, and biocompatibility.

-

Titanium Grade 5 Alloy (Ti-6Al-4V): A mix that offers extra strength and durability, highly corrosion resistant and used widely in medicine.

-

Zirconia: A metal-free option with great aesthetics, though it can be a bit more brittle.

Connection Types: How the Implant Pieces Fit Together

A crucial part of implant design is the connection between the implant fixture and the abutment (the part that holds the crown). This connection must be precise to ensure stability and prevent issues like micro-movements. Let’s take a closer look at the most common connection types and their sizes.

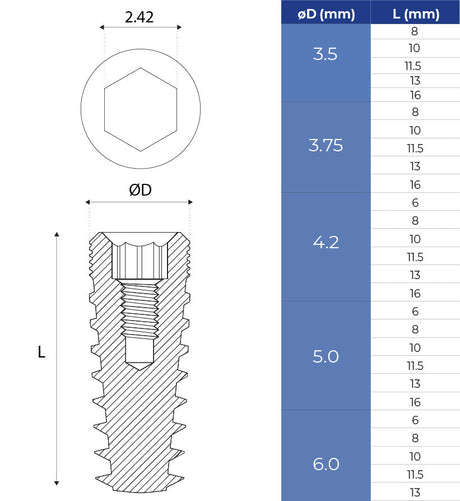

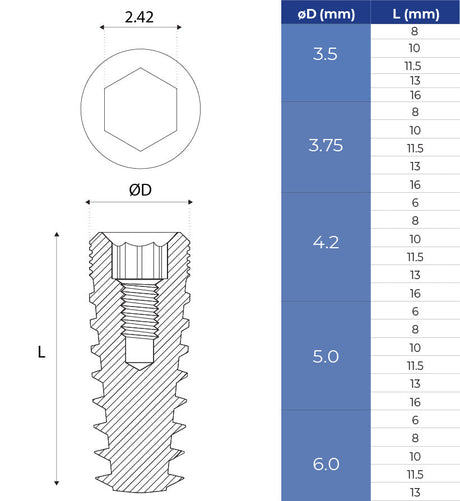

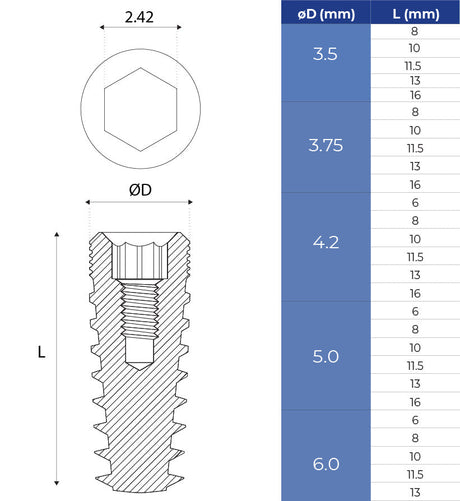

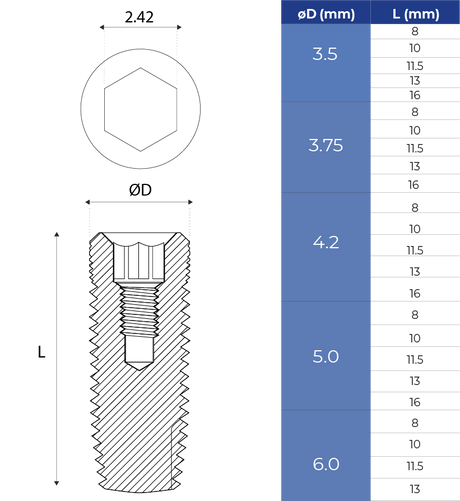

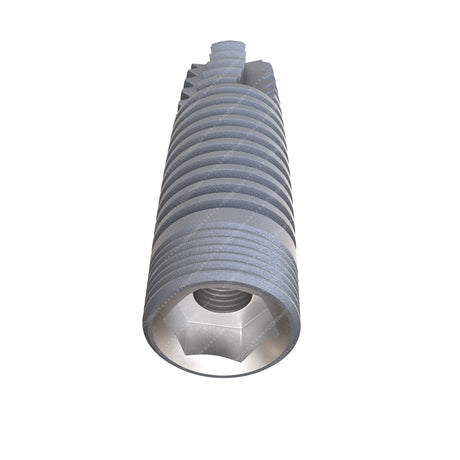

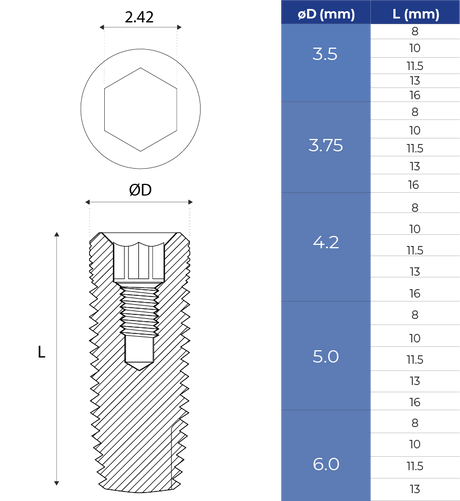

Internal Hex Connection

-

Overview:

The internal hex features a hexagonal (six-sided) recess inside the implant. This design helps prevent the abutment from rotating once it’s in place.

-

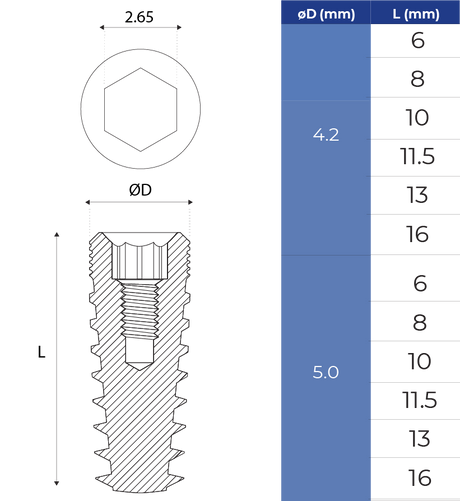

Sizes and Measurements:

Internal hex connections typically come in 2.0mm (slim) or 2.42mm (standard) diameters. The specific size depends on the implant system and the clinical situation. A larger hex can offer more anti-rotational strength, while a smaller hex might be used in compact areas.

-

Benefits:

This connection is widely used because it provides a reliable, secure fit and is easy to use during the restoration process.

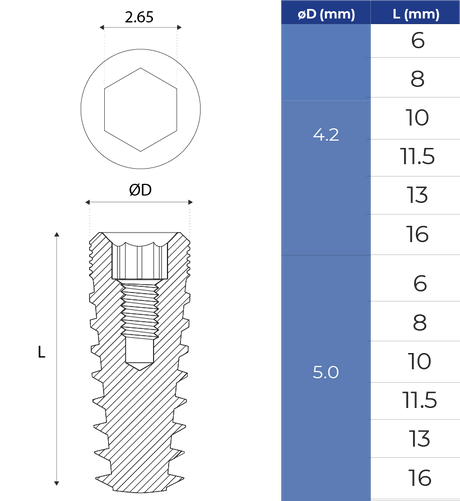

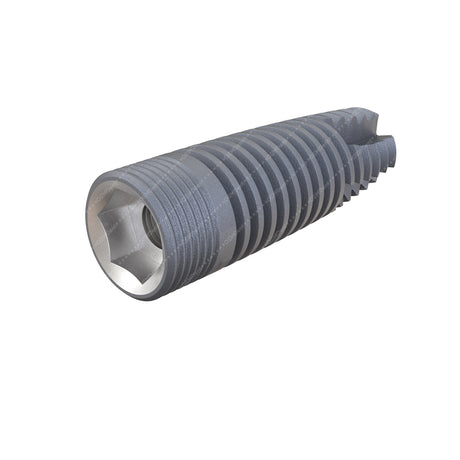

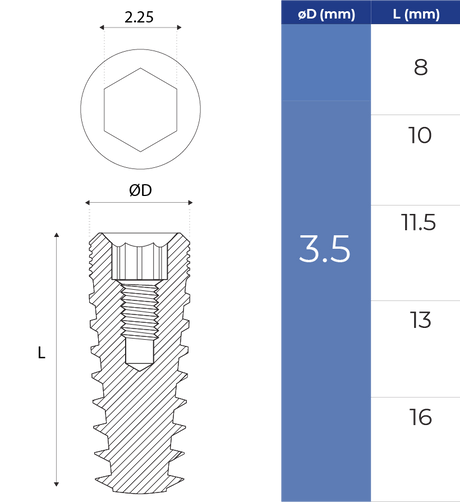

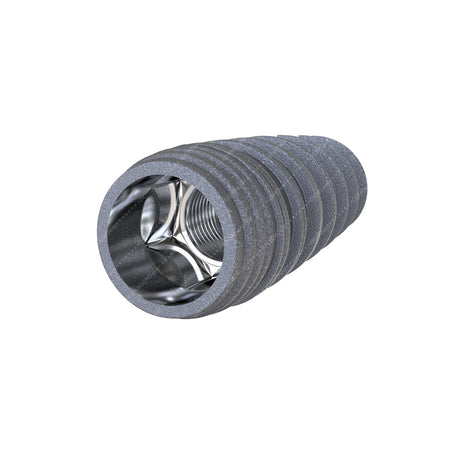

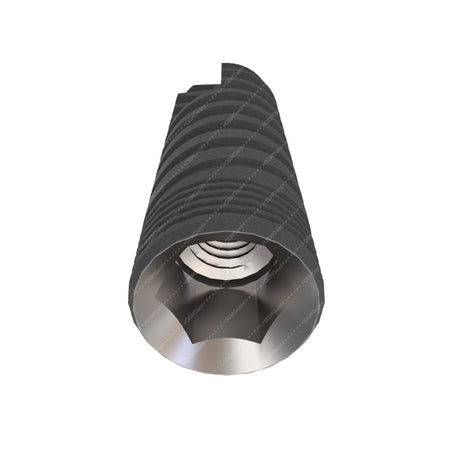

Conical Connection

-

Overview:

Conical connections use a tapered, cone-shaped design. This creates a friction-fit between the implant and abutment, leading to excellent stability.

-

Sizes and Angles:

-

Taper Angles: These connections often feature taper angles ranging from about 8° to 11°. The precise angle helps ensure a tight, snug fit that minimizes any micro-gap.

-

Dimensional Precision: Canonical connections typically come in 2.25mm (narrow) or 2.65mm (Regular) diameters.

-

Benefits:

The conical design not only improves the seal between parts—helping to prevent bacterial infiltration - but also enhances the overall mechanical stability of the implant.

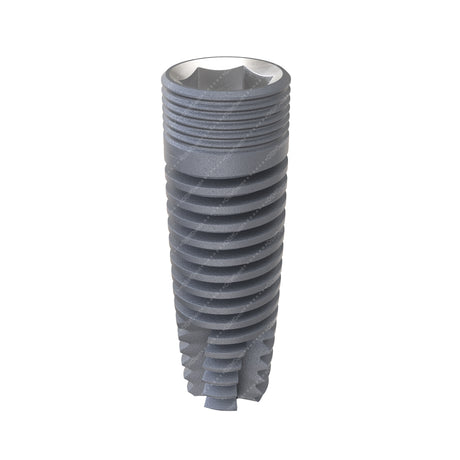

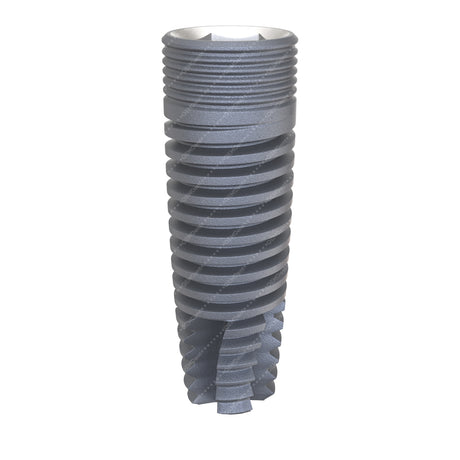

Morse Taper Connection

-

Overview:

Morse taper is a specific type of conical connection known for its self-locking, precise fit.

-

Sizes and Characteristics:

-

Taper Angle: Typically, Morse tapers use a very slight angle, often around 11.5° to 16°. This taper creates a secure fit through friction alone.

-

Dimensions: The Morse taper connection sizes are carefully engineered, with the mating parts often designed to interlock with diameters similar to those of other conical systems.

-

Benefits:

Its self-locking nature makes it extremely resistant to micromovements, which is crucial for long-term stability.

Other Connection Types

-

External Connections:

In some systems, the connecting part is on the outside of the implant. While historically popular, these are less common today due to potential issues with stability and aesthetics.

-

Key Considerations:

Each connection type is designed with specific clinical scenarios in mind. The choice depends on factors such as the available bone, the need for anti-rotational features, and the overall design philosophy of the implant system.

Selecting the Right Implant: Factors to Consider

Choosing the perfect implant is like assembling a puzzle. Dentists consider many factors to ensure success:

-

Bone Quality:

-

Type I Bone: Very dense, often in the front of the jaw.

-

Types II & III: A mix of dense and porous bone, common and usually ideal.

-

Type IV: Softer bone that might require extra support or a bone graft.

-

Implant Size:

-

Short Implants (6-8 mm): Suitable when there isn’t much vertical bone.

-

Standard Implants (10-13 mm): Proven for their stability in many cases.

-

Wide Implants: Used in molar regions to handle stronger bite forces.

-

Timing of Placement:

Looking Ahead: Innovations in Dental Implantology

The field of dental implants is continuously evolving. New technology is making implants even more precise and effective:

-

Digital Planning and Guided Surgery:

Advanced software now helps plan the exact position of implants, reducing risks and increasing accuracy.

-

Custom-Made Implants:

With computer-aided design (CAD), implants can be tailored perfectly to each patient’s anatomy.

-

Bioactive Coatings and Regenerative Therapies:

These innovations speed up bone healing and improve the bond between bone and implant.

OEMDent’s Role in the World of Compatible Implants

At OEMDent, our expertise lies in providing high-quality, compatible dental implant fixtures that work seamlessly with various brands. Our solutions are engineered with precision and offered at competitive prices, ensuring that dental professionals can achieve excellent outcomes without compromise.

Final Thoughts

Dental implants have transformed modern dentistry by providing strong, natural-looking, and long-lasting solutions. By understanding every aspect - from the basic design and materials to the intricate details of connection types and sizes, you can make informed decisions that lead to lasting success.

This guide is your friendly roadmap through the fascinating world of dental implants. Whether you’re refining your skills or exploring new innovations, remember that every great smile starts with a solid foundation and a willingness to learn. Let’s continue growing and innovating together in the exciting field of implantology!

Learn More

Learn More OEM Services

OEM Services